Crispbread & cooling technology – part 4

Ron Eerhart about the installation in Sweden, working abroad and fraternisation

A new project for a large fresh centre in Sweden. How do we approach that? In a number of blogs, we would like to take you into our world. In this blog: Ron Eerhart (chief technician) about the installation in Sweden, working abroad and fraternisation.

“Did you know that southern Sweden used to belong to Denmark? Just one of the things you learn when you work in Sweden for a long time!” Speaking is Ron Eerhart, chief technician at Voets & Donkers and (co-)responsible for the assembly of the installation built in the large new fresh centre for food processor VCN in Sweden. Ron was largely in Sweden from April to November 2019. Once every two weeks, he came home for a weekend, and during the construction holidays he was home for three weeks. The rest of the time he spent in Sweden, where he alternated hard work with a visit to the sports club, a restaurant in the area or the pub in Malmö.

Mishmash of nationalities

Under Ron’s leadership, some sixteen people worked on the installation, ten of whom were from Voets & Donkers itself and the rest were hired from other companies. These mechanics and welders were of course present in ever-changing teams, so sometimes four men were walking around, sometimes ten and sometimes sixteen. The team consisted of a mixture of nationalities: from Hungarians to Poles, from Swedes to Romanians and, of course, the Dutch. “That’s what I like best about this project”, Ron says. “That with so many different people with all these different nationalities and all these different characters, we were able to set up such an installation. Luckily, most of them spoke English well. Because it’s a complicated installation and a big project. But we got it done!”

”I think the best thing about this project is that we were able to create such a large and complex installation with so many different people of all these different nationalities!

Ron EerhartEerhartChief Technician

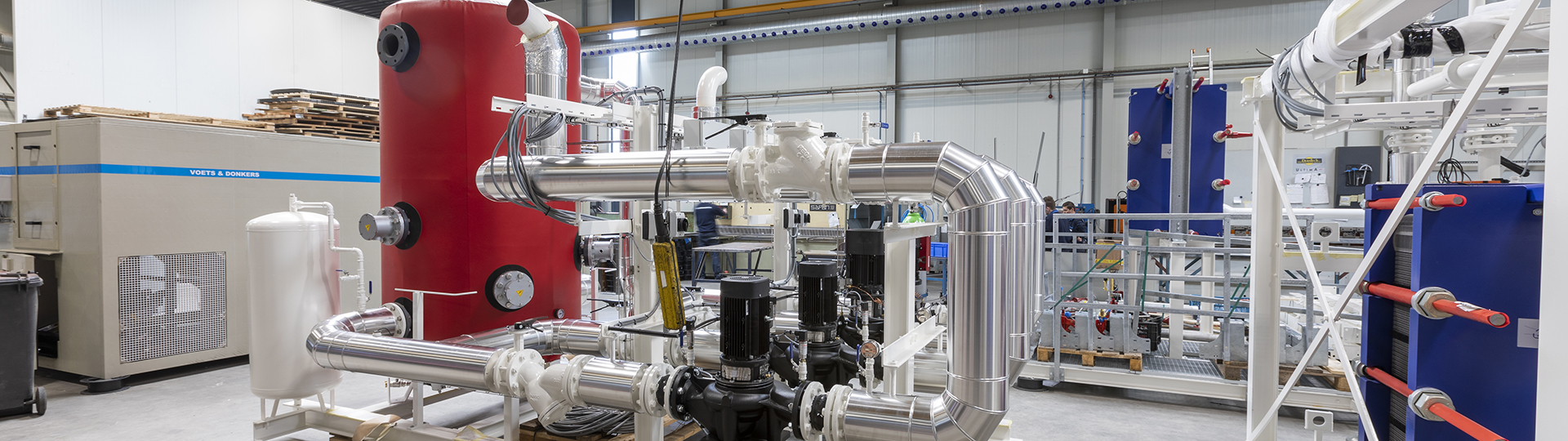

With almost 8,000 m2 of floor area, 3,000 kW of cooling power and a 12 by 16.75 by 8.7 metre machine room, the fresh centre can rightly be called a large project. What’s more, it’s an advanced project. Ron: “The residual heat we produce during cooling is used, among other things, for underfloor heating in the offices, to defrost the coolers and to heat the air treatment units in the building. This way, we ensure the reuse of energy and thus build a very sustainable installation.”

Tight planning

“In addition, the fact that the work has to be done in Sweden also made the project a little more complex than if it were to take place in the Netherlands. “It goes without saying that employees who fly to Sweden and have to eat, drink and sleep there are more expensive than those same employees on a project here in the Netherlands. That’s why every minute there should be spent efficiently, and that requires a tight schedule. Also with regard to the transport of the materials. There, we often had to think a bit further ahead: what still needs to be ordered and when can it be transported, so that it will be in Sweden on time? This means I had a lot of contact with my colleagues in the Netherlands via WhatsApp or, on the weekends that I was at home, at the office. It was a very intensive time for me.”

As chief technician, Ron acted as the eyes and ears of the project leader on location. He was in charge of the team, regularly sent reports and photos, and was also the point of contact for the employees. “On such a major project abroad, you’re more on each other’s lips, of course. Luckily, we got along fine. Of course there would be issues sometimes, and you have to discuss them, but we also laughed a lot and there was a lot of fraternising. You work hard together during the week. It’s physically taxing and you work long days. On weekends, you can do fun things together, such as swimming, an excursion or a barbecue. At a certain point, you truly become a group.”

Proud

A group that also did a great job. Because the installation is now in operation. “We’ve been monitoring the installation remotely for the past few weeks”, Ron says. “We can then log in to the installation and, among other things, monitor values, view photos and, if desired, start up or shut down compressors. A couple of times a day, we checked to see if everything was all right. At the beginning of January, four mechanics went back to Sweden to finish some loose ends. In week 4, another programmer will go there and then the installation can really be started. Great, isn’t it? I’m proud that we were able to achieve this together!”

Want to know more? Read the earlier blogs of Peter Donkers, Derk Alkema & Michael van der Meijden en Wilco de Laat here.

Sectors

Cheese maturation

As a cheese producer, you know better than anyone that there are countless types of cheese and that each cheese has its own properties. The air conditions in your warehouse play a major role in this; after all, they determine to a large extent how your cheese matures and (therefore) tastes. Voets & Donkers is a specialist in creating exactly those conditions that optimise cheese maturation and give your cheese its own characteristic and perfect taste.

Fresh produce

Optimum taste, quality and shelf life are of great importance in the fresh produce sector. At Voets & Donkers we have the knowledge, experience and expertise to offer added value as a refrigeration company. We have many customers in the fresh produce sector: from small-scale farms to large fresh centres. With cold stores and freezers in all shapes and sizes, we offer a wide range of possibilities. Whether it concerns a cold store on the farm, a vegetable-processing factory or a large (refrigerated) warehouse… we are at your service!

Sustainability

Sustainability is very important in our society today. We ‘have to’ get rid of the gas, and we also try to limit our use of electricity as much as possible. At Voets & Donkers, our installations contribute to sustainability in three ways: we use natural refrigerants, we develop energy-efficient installations and we make heat recovery possible.