Techniek Toekomst Magazine

A great article about Voets & Donkers in the Techniek Toekomst Magazine. This magazine underlines the importance of technical education and good professionals for technical companies. The magazine surprises and inspires! Are you curious about our article? Please find it below.

We are in great need of ‘cool’ professionals

The preservation and conservation of food becomes increasingly more important in today’s society. The aim is to reduce throwing away rotten food to a minimum. In the right conditions, it is possible to lengthen the shelf life of products, so they can be consumed at a later moment in time. Cooling technique plays a major role here.

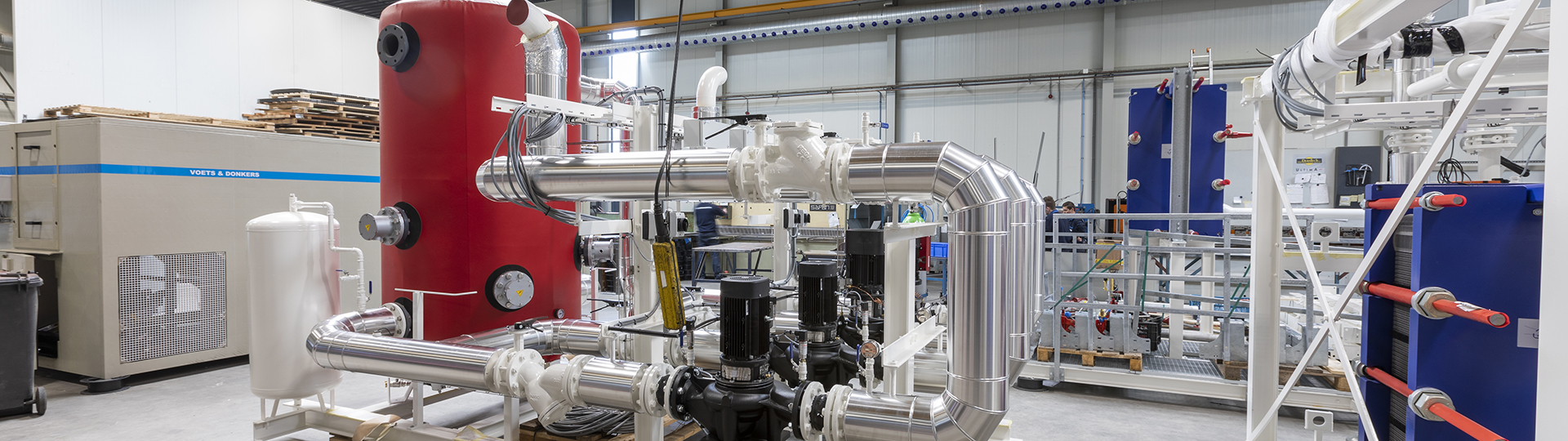

Voets & Donkers specialises in the development, production and installation of industrial cooling installations and air conditioning systems. Our strength is in the combination of innovative capacity and cost-efficient production: we have the know-how to think along with our clients, to create design, and we have the possibilities to manufacture professional products at low costs. Our field of expertise stretches across the full length of the industrial cooling and freezing technology and air conditioning, with a specialisation in the area of maturing of cheese, food processing, high-care, cleanrooms and air conditioning.

We make use of natural refrigerants to the highest possible extent, which reflects the sustainable character of our company. With a close-knit team of about 50 colleagues, we commit to achieve the best results for our clients, on a daily basis. Our mechanics support our quality and are given a lot of opportunity for own input. This makes working at Voets & Donkers challenging, but pleasant most of all. We offer our staff ample opportunities for (internal) growth and this allows us to always keep up and even lead the way in terms of innovative, new technologies. Having all the facets in-house, allows us to offer our technical staff useful and broad perspective in terms of personal development within the refrigeration technology.

Cheese

“We manufacture installations for, for instance, distribution centres and we are mainly active in the foodstuffs sector. We also assist many companies with regard to production and maturing of cheese. We see to cooling and air conditioning in most of the cheese storage facilities in the Netherlands.”

Optional subject refrigeration technology

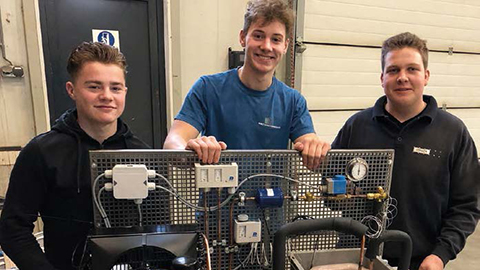

“Currently, the collaboration with the Elde College is rather intensive. John van Hoek, the father of one of my colleagues, is a lecturer at the Elde College. He invited me for a discussion on how to better reach youngsters. In the past, we supplied bits and bobs to familiarise students with refrigeration technology. As a guest lecturer, I explained refrigeration technology to the students and what can be done with it. Afterwards, three students wanted to know more about it and currently, they are attending the optional subject ‘refrigeration technology’ at Voets & Donkers. The boys are still young, but they are definitely interested. As a result of our collaboration, the Elde College now has two properly functioning cooling units. I am teaching the students how to operate them and what they could explain about them to their peers. Together, we stand for sound technical education, which is quite important! So, the Elde College has become an important partner for me in terms of educating students about refrigeration technology.”

Role within installation technology

“At Voets & Donkers, we generally believe that refrigeration technology will have an even more crucial role in the world of installation technology. There is continuous demand for cooling, as a result of which also a lot of heat is being produced. The use of this residual heat currently makes it possible to heat entire plants by use of the cooling installation. This makes a gas connection redundant for these clients.”

Job security

“The installation technology is technically challenging and offers a lot of future perspective. If this takes your fancy, refrigeration technology is something for you. Since you will scarcely have the opportunity to look into a pipe, you must understand what is going on in there. Physics make it possible to take up heat in one location and emit it in another location. It is an interesting and clean technology. We are in great need of ‘cool’ professionals. Increasingly more often, adolescents will choose an education that has a future. That future can certainly be found in the refrigeration technology!”

About Roel Gerritsma

Roel Gerritsma is general manager at Voets & Donkers Koeltechniek in Schijndel. He has a mechanical engineering background. At his previous employer, the Royal Airforce, he came in contact with refrigeration technology. The switch to Voets & Donkers was therefore nothing but a logical step for Roel. Roel: “With around 50 employees, we are a solid company in the refrigeration technology. The atmosphere in our company is informal and you can approach any of us. There is little turnover of staff, which is partly due to the great group atmosphere. We are a fairly small company, but what we create is grand and highly professional”.

Sectors

Cheese maturation

As a cheese producer, you know better than anyone that there are countless types of cheese and that each cheese has its own properties. The air conditions in your warehouse play a major role in this; after all, they determine to a large extent how your cheese matures and (therefore) tastes. Voets & Donkers is a specialist in creating exactly those conditions that optimise cheese maturation and give your cheese its own characteristic and perfect taste.

Fresh produce

Optimum taste, quality and shelf life are of great importance in the fresh produce sector. At Voets & Donkers we have the knowledge, experience and expertise to offer added value as a refrigeration company. We have many customers in the fresh produce sector: from small-scale farms to large fresh centres. With cold stores and freezers in all shapes and sizes, we offer a wide range of possibilities. Whether it concerns a cold store on the farm, a vegetable-processing factory or a large (refrigerated) warehouse… we are at your service!

Pharmaceuticals

The conditions under which medicines are produced, processed and stored are of great importance for their quality. As a pharmaceutical manufacturer or wholesaler, you need a reliable partner in this field. At Voets & Donkers we have extensive experience in creating exactly the right air conditions for the storage of medication.

Warehousing

Different wishes and requirements apply to each distribution centre or warehouse in terms of temperature and (ultra-clean) air conditions. With our knowledge and experience in industrial refrigeration technology and air treatment installations, we can optimise the quality and shelf life of the stored products.

Food products

As a producer or processor of food, you know that hygiene is essential. The air quality must be optimal so that no contamination enters the packaging or the product during processing or packing. At Voets & Donkers, we specialise in creating an ultra-clean air quality for the production, processing and storage of food products.

Sustainability

Sustainability is very important in our society today. We ‘have to’ get rid of the gas, and we also try to limit our use of electricity as much as possible. At Voets & Donkers, our installations contribute to sustainability in three ways: we use natural refrigerants, we develop energy-efficient installations and we make heat recovery possible.